Build Process

How To Build an ICF House - Typical Building Process with Altherm ICF

From foundations to super structure in 1 – 4 weeks, the following content outlines the typical building process based upon a pair of 100 sq m semi detached houses. Manpower crew refers to Altherm ICF approved installers.

Week 1

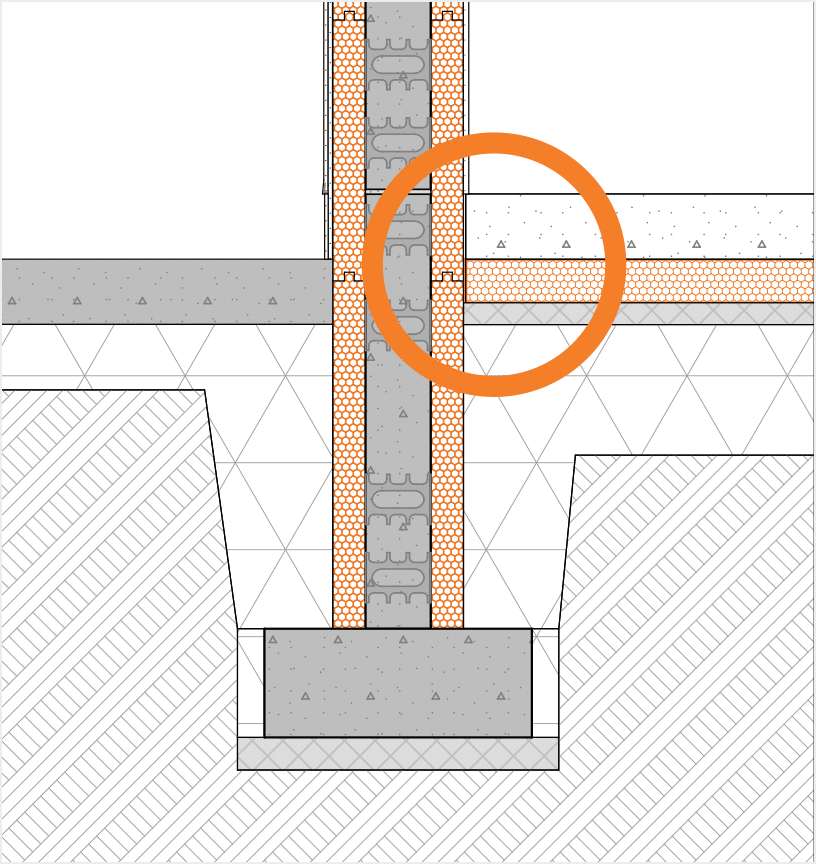

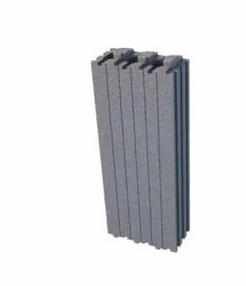

Foundation Rising Walls

Week 2

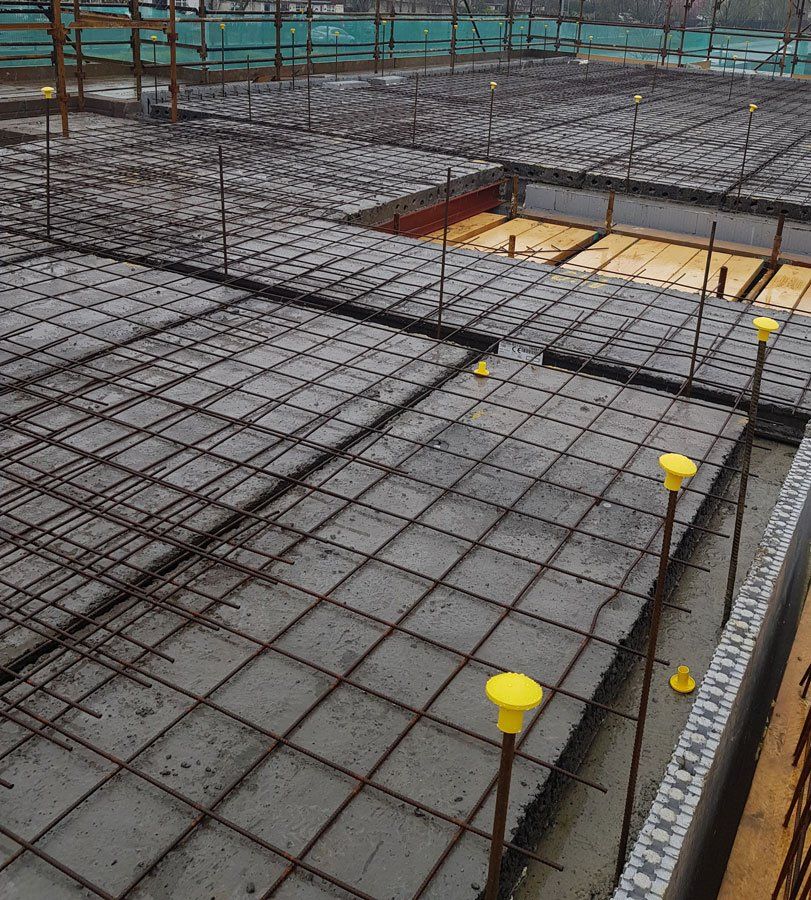

Ground Floor

Week 3

Joisting / Precast Flooring

Week 4