Why Altherm ICF?

The Altherm ICF System

Altherm ICF is an award-winning modern construction method designed to address the growing demand for high-quality housing that can be built quickly and at scale.

With the capacity to supply 3,500 homes annually, Altherm ICF offers superior thermal performance, excellent sound insulation, structural durability, and compliance with the latest fire safety standards.

It also offers significant cost savings compared to traditional construction methods, with faster site turnover and lead times of just a couple of days. Altherm ICF is certified by both NSAI Agrément and the BBA and holds ISO 9001 / 14001 / 45001 certifications as a testament to our commitment to quality and continuous improvement.

Our product range is designed to help you build homes that comply with building regulations and meet the new Part L requirements. Our low-energy, compliant ICF products will save you time, reduce costs, and ultimately enable you to build top-quality houses. They are also certified for use in the construction of buildings of up to six stories (18m).

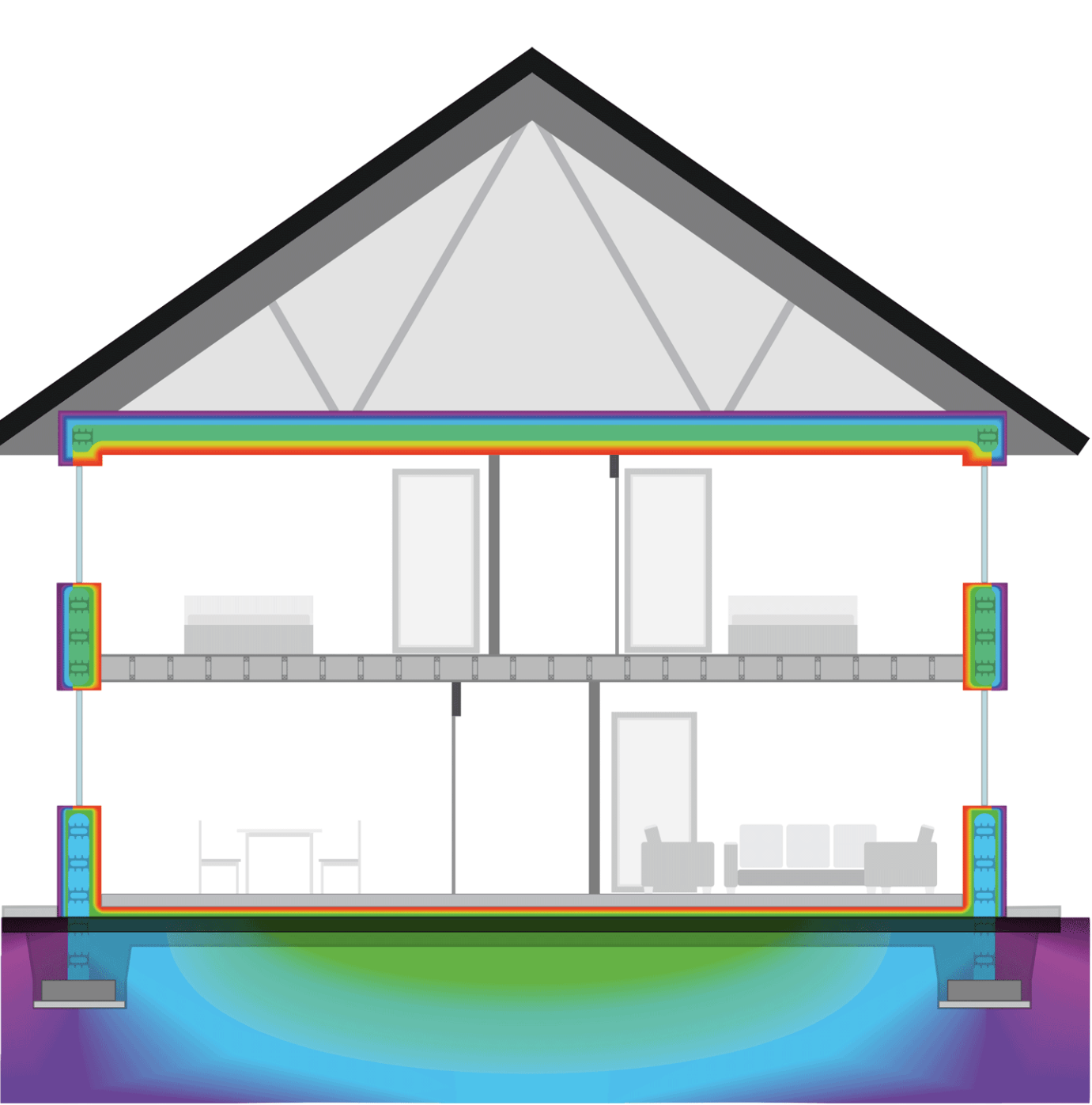

The thermographic diagram below illustrates how ICF assists energy efficient homes.

Using the Altherm ICF range of products, many certified housing projects have been successfully delivered for local authorities and housing bodies, including Cluid, Tuatha, Respond, HSE, IRES, and Urbeo.

How It works, in brief

For a more detailed

breakdown check out

a typical building process using ICF below.

1. Our hollow block wall system is made of flame-retardant expanded polystyrene (EPS). The blocks are comprised of two EPS panels, which are connected by polypropylene webs which provide a core thickness between the EPS panels of either 150mm or 200mm.

2. During construction, the hollow blocks are stacked in rows, and the cavity within is filled with concrete to form

the wall and the load bearing structure of the building.

4. Once the concrete has set, a concrete wall is formed. And this poured wall then retains the Altherm ICF EPS insulation on both sides, delivering further efficiencies.