Why Altherm ICF?

Benefits of the Altherm ICF system?

Why Altherm ICF - ICF products can help you:

-

Build Faster And Be More Productive

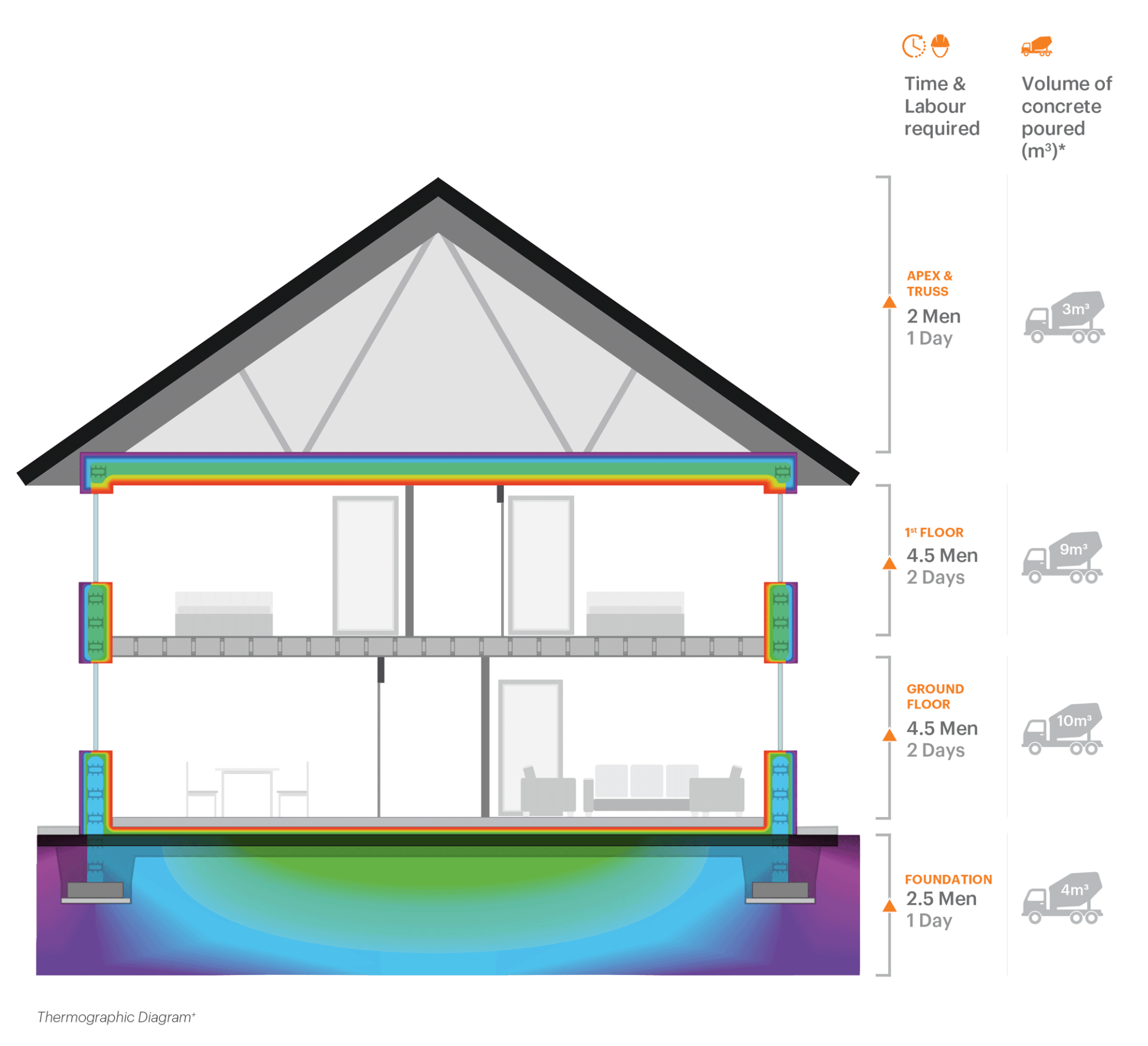

Highly efficient building is crucial. Using our product, a team can erect a pair of semi-detached houses from foundation to apex in approximately 12 days, substantially shortening programme time. Walls can be done in all weather and logistics is not an issue as our factory is only hours away from any construction site in Ireland.

-

Reduce Costs

Controlling build costs is always a major project concern. Minimal wastage means Altherm ICF houses are built very competitively and assembly crews can be trained easily to handle any potential skills shortages.

-

Stay Compliant

Altherm ICF meets the highest standards in quality and NZEB compliance, and contributes significantly to achieving NZEB and A ratings for finished houses. Homes built with Altherm regularly exceed soundproofing standards of >53db and easily surpass air-tightness levels of 3ac/h.

-

Maximise Health And Safety On-Site

Safety can never be taken lightly in our industry and Altherm ICF offers many advantages. It is light and easy-to-handle and requires only half the number of block-layers required onsite. And with no heavy machinery like cranes needed to move ICF around the site, this also significantly reduces the risk of on-site injury.

-

Is building with ICF a good idea?

ICF (Insulated Concrete Form) is a great option for constructing a house. Not only does it provide superior insulation compared to traditional methods of construction, but its flexibility and durability make it an ideal material for building projects.

ICF blocks can be easily cut and shaped, allowing for a wide range of design possibilities.

ICF’s characteristics ensure that homes built from this material have very high energy efficiency, while also providing excellent soundproofing and fire protection, over a very long lifespan.

ICF is also resistant to mould and pests, making it an incredibly safe option for any type of building project.

-

How long will ICF last? (What is the lifespan of ICF homes?)

ICF homes are known for their durability and longevity.

Altherm ICF homes have a certified lifetime of 60 years. In reality, with proper installation and maintenance, ICF homes can last far longer. This is due to the inherent strength and resilience of the reinforced concrete core of ICF walls, which provides exceptional protection against weather, fire, moisture, and other hazards. Additionally, the built-in insulation of ICF walls also contributes to a longer lifespan of the building by helping to prevent moisture damage due to condensation.

Although the initial cost of ICF construction may be comparable to traditional construction methods, the long-term savings and superior lifespan make it a worthwhile investment for any homeowner or builder looking for a reliable and sustainable building solution.

-

Maintain Quality And Prioritise Energy Efficiency

Optimum air-tightness and soundproofing is easily achieved with Altherm ICF while our proprietary cavity closers can eliminate cold bridging around window and door openings. In an era of carbon footprints and consumer energy awareness, house buyers are always looking to decrease energy usage and spend less on fuel.

-

Can I Build an ICF House myself?

In theory is possible to build an ICF house yourself, however we strongly recommend using properly trained and approved installers.

The reason for this is that although ICF is relatively easy to put up, it can be easy to make mistakes which could have costly consequences down the line.

Moreover, professional installers understand how to erect the ICF in accordance with the building regulations which must be followed when constructing a new property. For example, to ensure proper weatherproofing around windows, proper compaction of the concrete etc. – there are several aspects which you may not be aware of as a selfbuilder.

In addition to this, qualified professionals are also able to provide advice on specific techniques and other auxiliary materials which can help ensure your project has long-term strength and durability.

We believe that using qualified installers is by far the best way to build a safe and structurally sound ICF house.

One of the key strengths of constructing with ICF is the speed – this is something that comes to the fore with an experienced team. It is more time-efficient and cost-effective in the long run as experienced installers understand the design and construction process inside out and can manage any potential complications which may arise.

-

Are ICF walls Waterproof?

Altherm ICF walls are highly waterproof due to the monolithic reinforced concrete core and the low water permeability of the EPS insulation.

The concrete core of ICF walls is typically poured in a continuous, monolithic pour, which creates a strong and durable barrier against water and moisture.

Additionally, the EPS insulation used in ICF walls has an extremely low water permeability and is designed to keep moisture out of the interior of the wall. This means that ICF walls are highly resistant to water damage and can withstand even the harshest weather conditions.

-

Do ICF walls crack?

ICF walls are known for their superior durability compared to traditional construction methods. While it is possible for any type of wall to crack under certain conditions, ICF walls have a lower likelihood of cracking due to their reinforced concrete core and the fact that they are poured in a continuous, monolithic pour. This provides an extremely strong and durable structure to the home.

Additionally, ICF walls have built-in insulation, which helps to prevent temperature fluctuations that may lead to cracking in other types of walls. While no wall system is completely immune to cracking, ICF walls are a reliable and robust option for building construction.

-

Can mould grow on ICF?

Mould growth can be a common issue in many buildings, however ICF houses are specially designed to resist mould formation through the use of thermal models and proper ventilation design.

Detailed thermal modelling is used for designing ICF structures which is very effective in minimising condensation, which is one of the main precursors of mould growth. This is achieved by ensuring that heated air inside an ICF house is evenly distributed and does not create cold spots where condensation is more likely to occur.

Contributing to this also is the extremely low thermal bridging factor of ICF.

Furthermore, proper ventilation design in houses helps to reduce moisture levels. Modern houses are designed with a continuous flow of air from outside to inside and vice versa which helps keep the air at the right humidity levels and improving internal air quality.

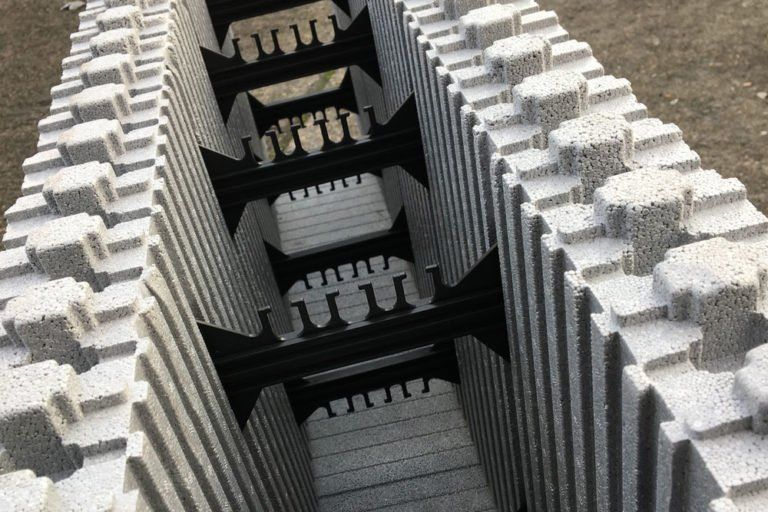

Our hollow block wall system is made of flame-retardant expanded polystyrene (EPS). The blocks are comprised of two EPS panels, which are connected by polypropylene webs which provide a core thickness between the EPS panels of either 150mm or 200mm.

During construction, the hollow blocks are stacked in rows, and the cavity within is filled with concrete to form the wall and the load bearing structure of the building.

Around openings like doors or windows, the cavity is formed by fitting our unique Altherm ICF cavity closers. Significantly decreases thermal bridging levels.

Once the concrete has set, a concrete wall is formed. And this poured wall then retains the Altherm ICF EPS insulation on both sides, delivering further efficiencies.

" The mindset change of bringing a house from green field to sealed envelope within 2 weeks really made up our mind on the product."

Robert Finn

Capcon Building

Airport Business Campus, Swords Rd, Santry, Dublin 9, D09 V8NT

Altherm ICF | Copyright